Contact

![]()

Grzywka Group

ul. Boguszewska 1

01-250 Warszawa

Telefon +48 780 002 024

Sales department:

biuro@grzywkagroup.com

Please contact us

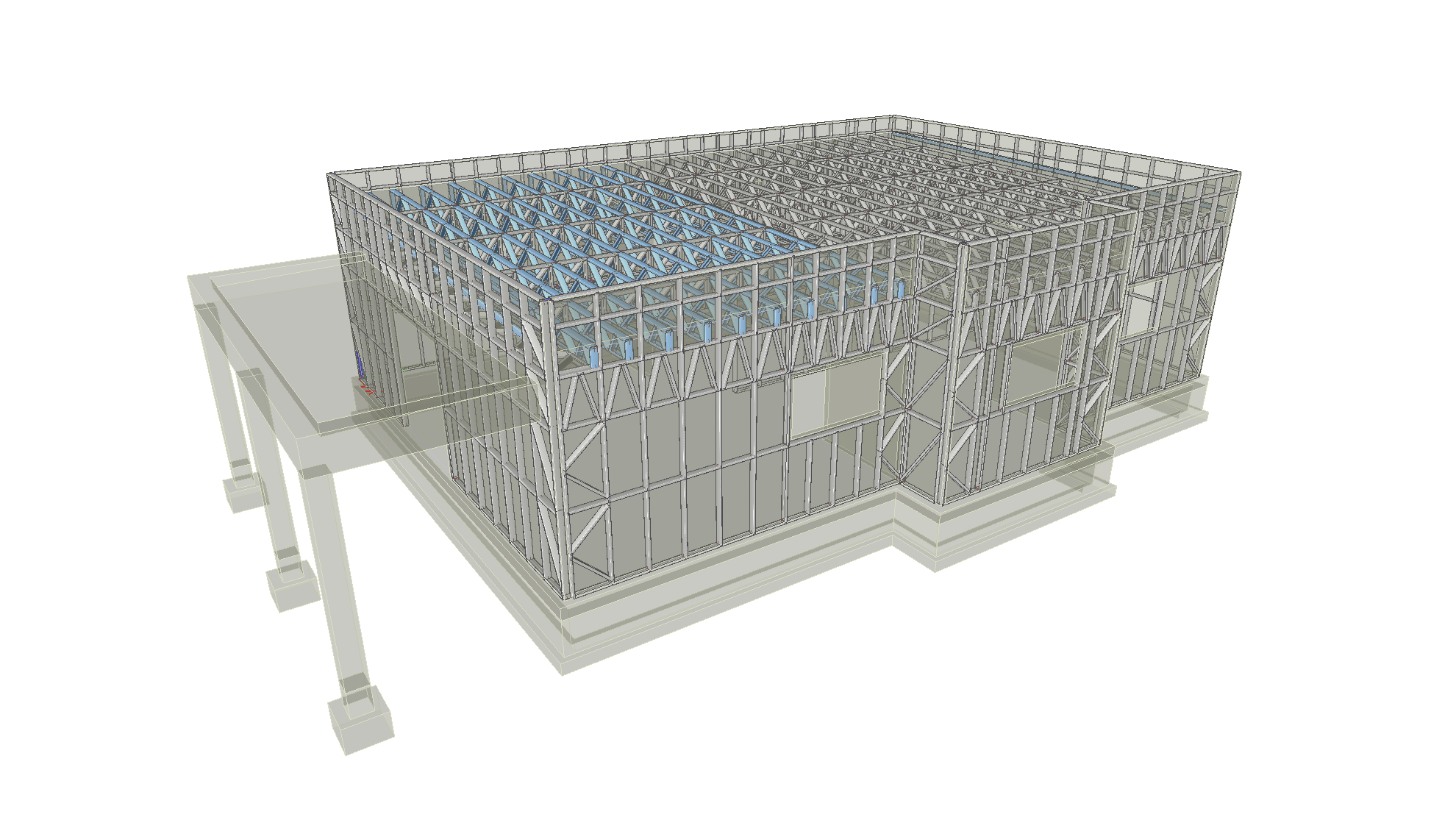

Galvanized steel structure SFH “Grzywka” technology is a durable, resistant, lightweight and fast to assembly building structure. Traditional masonry structures, although permanently upgraded, are still the most time-consuming and labour-intensive methods of building erection. In the age of mortgages and fast pace of life, when economic decisions are dictated by time and profitability by a particular way of erection, the cutting-edge technologies are becoming more and more popular. Our technology is the newest method of building erection, with the use of galvanized light gauge steel profiles, in the world.

An advanced system of steel elements production enables to produce high-tech structures used to erect various-purpose buildings and, above all, to built them precisely, quickly and cheaply.

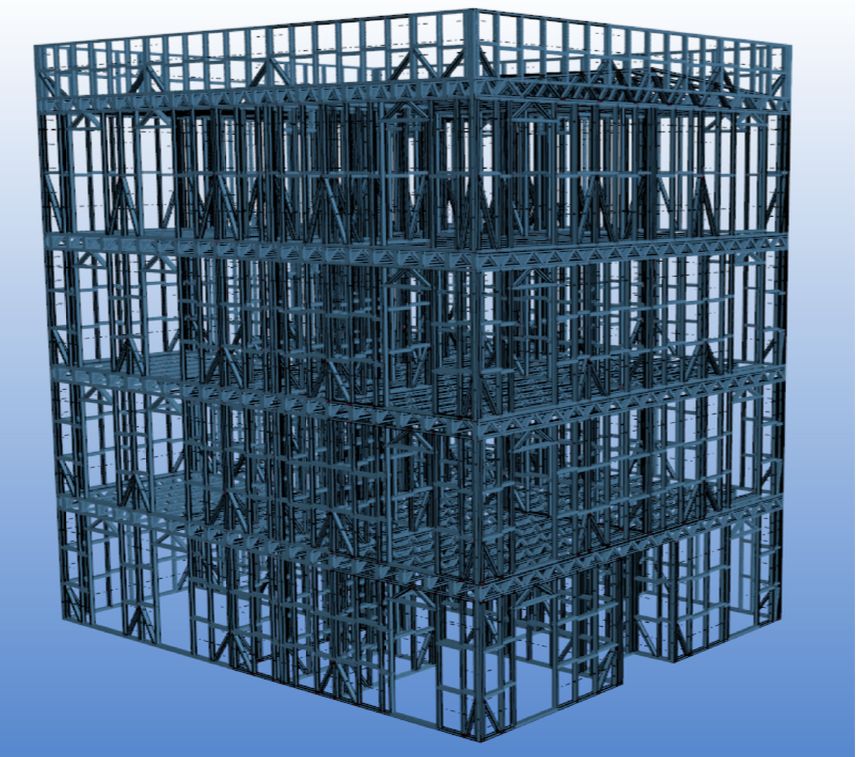

A skeleton is made of cold-bend, galvanized steel profiles which enable shaping various architectonic forms. This high-tech solution is an alternative to traditional technologies because each particular element, previously designed as a masonry one, can be redesigned in a light gauge steel method. Moreover, a light-weight structure as well as easy and fast assembly, in all weather conditions, underline its innovative character. Walls, made in this technology, have very good thermal parameters in relation to wall thickness. High-tech and computerized machines are used to produce construction elements, which guarantees the highest precision and accuracy.

All produced elements are properly tagged, which makes it easy and fast to assemble into wall panels, floor beams, roof girders, etc.

The system obtained the technical approval AT-15-9113/2013.

TECHNICAL DATA

Material

The profile is made of galvanized steel coil of 0,95 to 1,6 mm in thickness. We use S350GD+Z275 or S390GD+Z275 constructional steel. A galvanized coating is anticorrosive protection. Galvanized effect of zinc also protects edges of elements after extruding and cutting. Metal plates are galvanized accordingly to PN-EN 10152:1997. (The minimum thickness of zinc, double-sided measured, should be 20 µm, i.e. 275g/m2.)

Profiles

The main steel profiles, used in the SFH system, are channel-shaped profiles of 100×41,3×10mm. Profiles may have hydraulically pressed holes for installations and anchorages, if necessary.

Joints

All elements are joined with galvanized screws or rivets.

Walls

Wall panels are prefabricated from C-profiles. Wall studs in panels are 60 cm apart. In addition, panels are strengthened by diagonal bracing or cladding, such as OSB, MFP or Duraline boards. A prefabricated wall panel has got window and door openings, as well as indispensible holes for electrical and sanitary installations.

Ceilings

Floor beams are based on trussed beams. The height of beams depends on the span. In case of small spans or unserviceable ceilings, we can apply floor panels. The maximum span of a beam is 12m and the typical spacing is 60cm.

Roofs

The typical load-bearing structures of a roof are truss girders or roof panels. Truss girders are used in case of unserviceable attics. Roof panels are usually supported by partition walls in the attic.

Foundations

In case of light steel structures, it is recommended to use foundation plate; however, it is not obligatory. The strike price of a foundation plate, in comparison to a continuous footing, is much more cheaper for skeleton structures than for traditional ones.

Why the steel skeleton?

![]()

Grzywka Group

ul. Boguszewska 1

01-250 Warszawa

Telefon +48 780 002 024

Sales department:

biuro@grzywkagroup.com

Please contact us